Refueling truck is mainly used for the transportation and storage of petroleum derivatives (gasoline, diesel, crude oil, lubricating oil, coal tar and other oil products). The mobile gas vehicle is equivalent to a mobile gas station, which can supply fuel to the required vehicles anytime and anywhere.

Tank materials: there are carbon steel, stainless steel, aluminum alloy and other materials can be selected to make the tank.

Shape of tanker : it is divided into oval tank, round tank and square round tank.

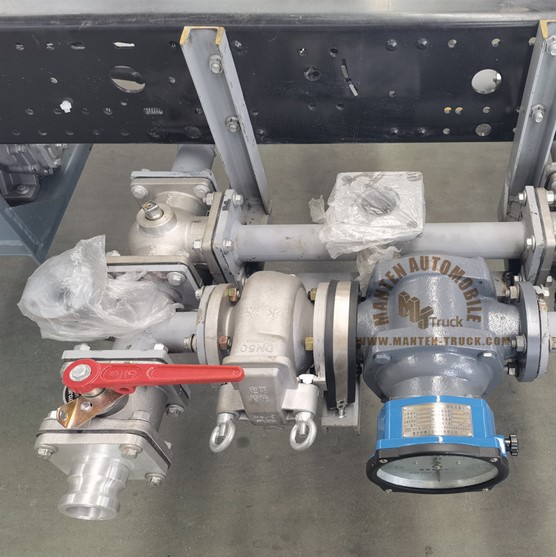

Functional configuration: equipped with fuel dispenser, fuel reel with fuel gun, flowmeter and liquid level meter,oil display meter, oil quantitative control operating system and so on.